🛡️ Shielding Your Assets: The Ultimate Guide to Corrosion Inhibitor Chemicals in India

“Corrosion doesn’t make noise. But it does make losses.”

Across ports, pipelines, power plants, and process industries in India, corrosion is the invisible enemy that weakens infrastructure, increases downtime, and erodes profitability. From marine operators in Mumbai to oilfield engineers in Gujarat, the need for corrosion protection has never been more urgent.

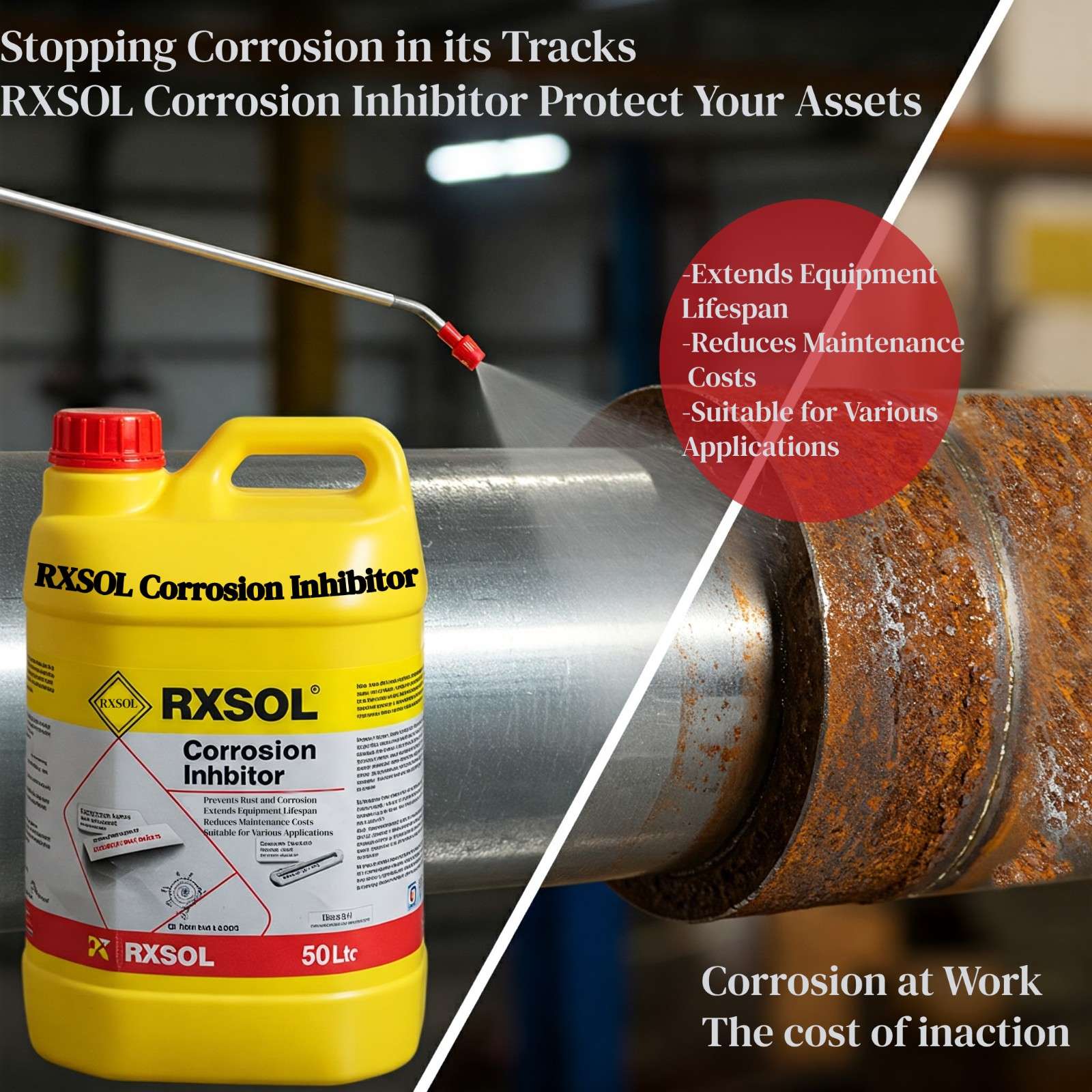

Enter the hero of this story: the RXSOL Corrosion Inhibitor chemical — your first line of defense against metal degradation, rust formation, and electrochemical damage.

In this blog, we’ll break down everything you need to know about corrosion inhibitor chemicals in India, how they work, where they’re used, how to choose the right one, and how they save you money while protecting your assets.

🔍 What Is a Corrosion Inhibitor?

A corrosion inhibitor is a specialized chemical compound that slows or prevents the corrosion of metal by forming a passivation layer or neutralizing corrosive agents like oxygen, acid, or moisture.

Corrosion inhibitors fall under a broader family of chemical inhibitors and come in various forms:

- Oil-soluble corrosion inhibitors (for crude oil pipelines, drilling rigs, refineries)

- Water-based corrosion inhibitors (for boilers, cooling towers, HVAC systems)

- Eco-friendly corrosion inhibitors (based on chitosan and other biopolymer inhibitors)

- Amines, hydrazine, and benzotriazole (used in boiler systems and copper piping)

⚙️ How Do Corrosion Inhibitors Work?

Corrosion inhibitors protect by:

- 🧪 Forming a protective film on the metal surface

- 🔬 Using the adsorption isotherm principle to physically or chemically adhere to metal

- 🌡️ Reducing oxidation, moisture permeability, or pH reactivity

- ⚛️ Interfering with the electrochemical reaction between metal and corrosive ions

🏭 Applications Across Indian Industries

India's industrial diversity demands highly specific corrosion solutions. Here’s how corrosion control chemicals are used across different sectors:

🛢️ Oil & Gas

Used to protect pipelines, storage tanks, and downhole equipment. Our oil & gas corrosion inhibitor line is formulated to work in extreme pressure-temperature (HPHT) environments, often using sodium sulfide and oil-soluble bases.

🌊 Marine

From ballast tanks to deck equipment, marine corrosion inhibitors are specially designed to combat salt spray, humidity, and electrolysis in coastal environments.

🔧 Manufacturing & Metalworking

Used as rust inhibitors, metal protector chemicals, and passivators for tools, steel sheets, coils, and tanks. Especially useful in surface preparation for coating or painting.

🔥 Power & Energy

Our boiler corrosion inhibitors and cooling water corrosion inhibitors in India are trusted in thermal, nuclear, and hydro power plants to improve thermal efficiency and prevent failures.

🚗 Automotive & Rail

Anti-corrosive treatments for radiators, chassis, fuel tanks, and engine blocks, using advanced metal protection coatings and non-toxic vapor-phase inhibitors.

🧪 Types of Corrosion Inhibitors We Offer

Water-based corrosion inhibitor: Cooling towers, HVAC systems, mild steel systems

Oil-soluble corrosion inhibitor: Refineries, pipelines, offshore rigs

Rust inhibitor: Workshop tools, stored metal equipment

Eco-friendly corrosion inhibitor: Food-grade facilities, eco-sensitive zones (based on chitosan, etc.)

Boiler corrosion inhibitor: High-pressure steam systems (using hydrazine, amines, etc.)

✅ Benefits of Using Corrosion Inhibitors

- 🛡️ Metal protection from rust, oxidation, pitting, and acidic corrosion

- ⚙️ Maintains system efficiency and reduces energy loss in boilers & heat exchangers

- 💰 Cost savings on equipment replacement, unplanned maintenance & asset loss

- 🌍 Available in eco-friendly formulations to meet environmental compliance

- 🔐 Extended shelf life for stored metal goods via vapor-phase inhibitors

💡 When Should You Use a Corrosion Inhibitor?

You should consider applying a corrosion inhibitor chemical if:

- You're facing frequent rusting on metal surfaces or machinery

- Your plant is near a coastal or humid area

- You use cooling towers, steam systems, or closed-loop water systems

- You transport or store uncoated or passivated metal components

- You're preparing for painting, coating, or galvanizing processes

💼 Packaging & Availability

We supply corrosion inhibitors across India in:

- 500 ml, 1 L, 5 L, 25 L, 50 L, and 200 L drums

- Tanker loads for large-scale industries

- OEM & private labelling options

- Documentation: MSDS and technical data sheets provided

🧠 Frequently Asked Questions

Q1: What’s the best corrosion inhibitor for pipelines?

Our oil-soluble inhibitors are designed for oilfield applications, with high thermal resistance and compatibility with hydrocarbon streams.

Q2: Can one product act as both rust and corrosion inhibitor?

Yes! We have combo products that offer metal corrosion protection and rust inhibition in one treatment.

Q3: What’s the average corrosion inhibitor price in India?

Depends on volume, base formulation, and usage. Contact us for a competitive quote.

Q4: Can I use it on stainless steel and copper?

Absolutely. We offer benzotriazole-based inhibitors for copper alloys and non-reactive passivators for stainless steel.

Q5: Do you offer eco-friendly or non-toxic options?

Yes, our biopolymer inhibitors and chitosan-based formulations are non-toxic and ideal for sensitive industries.

📞 Ready to Stop Corrosion in Its Tracks?

Whether you manage a boiler system, a fleet of ships, or a plant with high-value metal equipment, corrosion is inevitable — but preventable.

🧪 Contact us today to:

✅ Get a technical consultation

✅ Buy directly from India’s leading corrosion inhibitor supplier

Please feel free to reach out to us to place your order by shooting us an email at rxmarinechemical @ gmail . com

Think Metal Protection. Think RXSOL.