Iron Ore Red Dust Cleaner Usage Directions

Directions for Use

In general Dilute 1 part Iron Ore Red Dust Cleaner with 4 parts water and spray onto the surface being cleaned, And allow Iron Ore Red Dust for 20 to 40 Minutes to penetrate.

And For Hard Deposits Vigorously agitate the on the surface being cleaned with a stiff bristled brush or broom. And allow Iron Ore Red Dust for 20 to 40 Minutes to penetrate. Again, vigorously agitate the surface. The iron ore will begin to break up and be released from the substrate.

Stubborn areas may need to be again saturated and left for a further 10 minutes before vigorously agitating.

Rinse the surface with a high pressure washer or hose until all dissolved concrete and Iron Ore Red Dust Cleaner has been removed from the surface being cleaned.

Test Iron Ore Red Dust Cleaner on a small inconspicuous area before use.

Do not apply Iron Ore Red Dust Cleaner undiluted.

A more concentrate dilution may be required where concrete has been cured for an extended period of time.

Do not leave Iron Ore Red Dust Cleaner on any surface for extended periods of time.

To maintain product integrity, keep container sealed when not in use.

A Simple Test to separate Ethanol and its unwantingly added water is to add POTASSIUM CARBONATE to separatethem out. This offers a very small potassium carbonate impurity to the alcohol that can be removed by distillation. This method is very useful in purification of ethanol by distillation, as ethanol forms an azeotrope with water.

Why RXSOL CORROSION INHIBITOR for cooling Water System Required ?

Corrosion damage metal surface by chemical or electrochemical reaction which results failure of equipment with the resultant cost of replacement and plant downtime.

Due to Deposition of CORROSION result fouling in of heat exchanger fouling caused by the accumulation of corrosion products., Heat Transfer efficiency decreases. Which resulting loss of plant efficiency due to loss of heat transfer.

HOW to CONTROL CORROSION in COOLING SYSTEM?

Primary Step : Use calcium carbonate bleanded RXSOL-40-4090-025 to increase alkalinity in the water which results to form a protective film on METAL SURFACE.

Second Step : Remove the corrosive oxygen from the water, either by mechanical or chemical deaeration Oxygen Scavenger RXSOL-50-5023-025. Excess of OXYGENT is mother of CORROSION.

Third Step : Add corrosion inhibitors RXSOL-40-4011-025

Which material is used to protect COPPER METAL in Water System?

Copper Corrosion Inhibitors. The most effective corrosion inhibitors for copper and its alloys are the aromatic triazoles, such as benzotriazole (BZT) and tolyltriazole (TTA).

#CorrosionInhibitor_SupplierAbudhabiFujairah

#CorrosionInhibitor_SupplierSoharMuscatOman

Depending upon contamination dilute concentrate with 10-25% with fresh water. In general terms take 1 Ltr concentrate and mix with 3 ltrs fresh water. For effective cleaning of air coolers, scavenging air systems and turbo chargers of diesel engines. As practical we observed that for engine capacity upto 12000 HP, 2 -3 ltr mixed diluted solution can be circulated for approx 10 - 15 minutes, Then followed by fresh water rinsing. While with higher and more engine power like engine power upto 24000 HP cleaning solution upto 5 ltrs while for engine power more then 24000 HP, 6 Ltr diluted cleaning solution required. . After uses of cleaning solution flushing with fresh water to clean complete emulsified deposit is a wise decision.

Otherwise doses can be calculated as per surface area. 3 to 5 litres of cleaning solution per square meter.

In General circulation: Depending upon contamination 10-25% with fresh water.

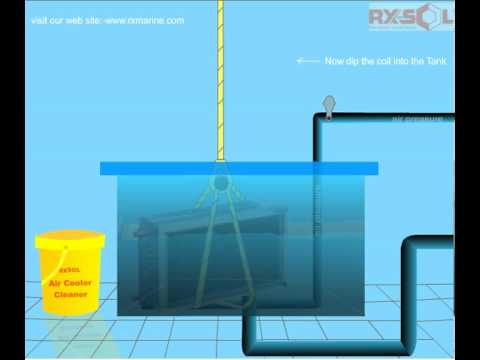

OPTIONAL: Dependant on design, the cooler is flooded with AIR COOLER CLEANER immersed in a tank full of product.

Hand spray Cleaning: By Hand spray, apply concentrate RXSOL-16-0009 all over the cooler coils. for good emulsification &penetration. Allow the RXSOL-16-0009 for a minimum of 10 MINUTES then use a high presure water to wash off the loosened deposits. During process always keep drain valve open. After satisfactory cleaning, and flushing through with fresh water, close air cooler drains.Note that during this process the engine must be stopped.

Immersion bath

Atleast for 2 Hrs deep COOLER PARTS in to AIR COOLER CLEANER emulsion tank. The product should be heated to approx. 50°C and agitation provided with an air line. Then drain off and flush well with water, followed by drying with an air line.

Soak method: Machine parts with stubborn carbon deposits to be cleaned is dipped into conc. Soln.of ACC then allow deposits to. Be broken down and loosened before removal, then rinse .

Circulation method

Some designs of cooler can be circulated "in situ". In this case a pump tank and pipe system is fitted permanently or connections are provided for connecting a temporary circuit. The system should be filled with AIR COOLER CLEANER circulation carried out for 2 - 4 hours at a temperature of upto 50°C. After cleaning the cooler should be thoroughly flushed with fresh water and dried with an air line.

Note: Both cleaning methods benefit from heat of up to 50°C and cleaning times can be reduced or extended dependant on temperature and degree of fouling.

Diesel Engine contains heavy contamination of loose oil, Grease, Carbon deposits. ACC9 plays role to dilute such deposits with strong emulsification effect without manual scrubbing which is damaging metal finishes. AIR COOLER CLEANER is a solvent based concentrated liquid solution with powerful surfactants based emulsifier, corrosion inhibitor swhich helps to loose completely deposits of oils, grease, soot and other carbonaceous deposits from machinery parts.

In marine Industries Air cooler Cleaner also popular as ACC-9. Air Cooler cleaner ACC9 can be mixed with water in a cleaning tank then as per dependent of design, the cooler can be flooded with AIR COOLER CLEANER mixture by dipping in a tank. For enhancing cleaning action this water mixed product can be heated to approx. 50°C. Click here for ANIMATED TYPICAL cleaning Method. (

)

Carbon Remover also can be mixed with Air cooler cleaner to clean all types of diesel engine and heavy carbonized part remove oil, grease and carbon deposits from air coolers and scavenging systems. ACC9 is mixture of powerful solvent emulsion making surfactants, strong emulsifiers and penetrating agents formulated to penetrate and remove all oily deposited materials from diesel engine air coolers, scavenging air systems and compressor sides of turbochargers.

ACC-9 also named as Turbocharger cleaner, Compressor cleaner, Diesel engine cleaner. Challenging product since 1995. Highest market share in India and Middle East giving us opportunity to make ACC9 in Bulk reactor of 4500 Ltr at a time in well defined glass reactor which is resulting Lowest price of ACC9 with pure and concentrated formulation.

AIR COOLER CLEANER dissolves all types of oily greasy carbonaceous residues deposits which is working as a suitable media of FIRE to move from one place to others. And deposition of grease and other fouling materials also reduce heat transmission effect, its proper cleaning increase engine efficiency. And proper maintenance and chemical cleaning of cooling system save Downtime and also chemical cleaning maintain finishes of all metal surface as new parts, While manual scrubbing and cleaning spoil surface finishes.

Since 1995 we are largest suplier of Air cooler cleaner in Kandla, Mumbai, Chennai, Kolkata, Fujairah.

Customized packing available.

Note : Due to presence of emulsifier in Air cooler cleaner, Its storage life is limited. And our experiment shows that its effective action also degrade after specific period of time. So we are only manufacturing ACC9 as per our fixed customer demand everymonth. THis will help us to make supply freshly prepared materials to get optimum results.

AIR COOLER CLEANING CHEMICAL ACC9 is one of best marine classified solvent based cleaner which effectively cleans all deposits of Turbo Charger and AIR COOLER. Its advanced formulation easily emulsifies to clean oil, grease and carbon residues from all components of air coolers, turbochargers and many other machinery parts of scavenging systems. Proper cleaning of carbon deposits from machinery parts helps maintain air cooler efficiency without any loss of cooling effect.

Air cooler cleaning chemcial principally formulated with solvent as a penetrating agent to loose all heavily deposited carbon grease, mud etc while other hands its heavy-duty emulsifier contents makes all loosen parts easily soluble in water. Uses of ACC9 limits mechanical cleaning and scrubbing which is damaging finishing of metal parts.

We are keeping ready stock of ACC9 in Jakhau, Mandvi, Mundra, Kandla, Tuna, Sikka , Bedi , Vadinar , Pipavav , Dahej , Hajira , Nhava Seva , Goa, New Mangalore , Cochin , Tuticorin , Chennai , Vizag, Mumbai, Kolkata, Haldia, Paradip and Middle East - Fujairah, Dubai, Sharjah.

Pl. feel free to ask for any customized packing from our DIRECT STOCK POINT - Visakhapatnam, MUMBAI, Chennai - Ennore, Kolkata, Kandla, Surat.

Our strong formulation of ACC9 can save your precious money and time. To avoid any duplication directly mail us your querry : mail@rxmarine.com

ACC PLUS is popular in marine sector to clean Diesel Engine Air Cooler and turbocharger compressor. Its effective surfactant formulation with Solvent easily dissolve hard oily and carbonecious deposits. Proper uses of ACC PLUS increases cooling efficiency of AIR COOLER.

Our New advance formulation of ACC PLUS air cooler cleaner also helps to clean and degreas maintainence area. And this product is fully water soluble after dilution with ware ACC plus can be use as degreaser also. And diluted solution of ACC PLUS can be kept in open cut drum or water bath, to clean daily uses of nut bolt and machinery parts. Simply dip oil contaminated parts in to diluted solution of ACC PLUS and keep for small period of time, this method can keep all maintence part clean and rust free. Here we can see that ACC PLUS having multiple cleaning action, Its presence on ENGINE area can avoid any additional degreaser requirement.

ACC Plus available with us in various size and packing of 20, 25, 50, 210 Ltr

For ACC Plus price and other related document like MSDS of ACC PLUS, you can mail us your inquiry ::: mail@rxmarine.com

Cleaning Tank is one of the most important tasks. To clean tanks after cargo discharge perfectly, use RXSOL Tank Cleaners. RXSOL Tank Cleaners comprise of more than 100 products related to the tank cleaning chemicals. After cargo discharge it is very important for the tanks to be clean so that the tank can be used to keep the next cargo. RX Marine International is one of the largest Tank Cleaner manufacturers and suppliers in Mumbai, JNPT, Nhava Sheva, Gandhidham, Kandla, Mundra, Surat, Kolkata, Howrah, Paradip, Haldia, Diamond Harbour, Vishakhapatnam, Chennai, Tuticorin, India, UAE, Canada. Buy one of the most efficient Tank Cleaners from us to clean your tank after cargo discharge.

We are also manufacturing and supplying Tank Cleaner in Kolkata, Howrah, Paradip, Haldia, Diamond Harbour, West Bengal, India. Our manufacturing plant in Vishakhapatnam is also one of the largest Tank Cleaner manufacturer and supplier in Vishakhapatnam

RXSOL Tank Cleaners comprise different Tank Cleaning product: each product for cleaning of specific cargo residue. Now that you briefly know how to clean tanks after cargo discharge, we shall look into the steps that must be followed to clean Tank after cargo discharge.

Steps to clean Tank after cargo discharge:

SprayingThis can be beneficial as part of the initial cleaning process after the carriage of Lube oils and Lube oil additives. As soon as the tank in question has been checked empty by the attending surveyor, RXSOL-20-2029-020 Plus should be sprayed over all surfaces which are safely reacheable.

Portable machines– After 45 minutes the butterworth machines should be operated for 3 x 20 minutes drops using warm 60o C, then the machines brought back to the top and a full hot wash 80 – 85 o C should be carried out for at least 6 hours.

Fixed machines– Wash ambient for 45 minutes followed by warm water for one cycle before increasing to hot (80oC) for 4 hours.

Injection – This can be carried out by injecting RXSOL-20-2029-020 Plus into the butterworth system after the heater. A normal amount to use would be 100 – 150 liters during the initial washing cycle. Water temperature should be 60o C during the injection period then brought up to 80 – 85 o C for the full washing period.

Re-circulation

– Possibly the best result are achieved by re-circulating a solution of RXSOL-20-2029-020 Plus after the initial rough washing of the tank. A sufficient amount of fresh water to maintain good suction should be heated to 60 o C and approximately 420 liters of RXSOL-20-2029-020 Plus (2 drums) added for each 500 liters of fresh water. The temperature of the mixture can be increased depending upon the melting point if the product being cleaned. The solution should be circulated for at least 4 hours and the butterworth machines operated at maximum pressure in all areas of the tank throughout this process. If a number of tanks are to be circulated, then a substantial quantity of solution can be made so that transfers can be made without delay and any small amounts lost will not affect the operation. Normally following transfer to another tank, 100 liters RXSOL-20-2029-020 Plus is added for each 5000 liters of solution. This is called “spiking”.

To get assisstance over the call regarding: How to clean tank after cargo discharge

Mail us at: 123@rxmarine.com

We manufacture and supply one of the best, highly efficient and easy to use Tank Cleaners. RX Marine International is supplier of Tank Cleaner in Mumbai, Nhava Sheva, JNPT, Maharashtra. We are also suppliers of Tank Cleaners in Gandhidham, Surat, Ahmedabad, Vadodara, Kandla, Mundra, Gujarat. We also have presence in Tamil Nadu as Tank Cleaner manufacturer, supplier and distributor in Chennai, Tuticorin.

Tank cleaner detergent helps to enhance cleaning action through high pressure machine. Tank cleaners are classified in various grade and type, based on there formulation and cleaning demand. Its major classified groups are as follows :::

Alkaline Tank Cleaner

Neutral Tank Cleaner

Solvent Based Tank cleaner

Acidic Tank Cleaner

Odour Removing Cleaner

Colour Remover

And More then 50 tank cleaner are available thorugh this link http://rxmarine.com/TankCleaner-20

We are one of popular and largest tank cleaner supplier in KANDLA, Sikka, Mundra, Mumbai, JNPT, Goa, Manglore, Visakhapatnam, Chennai, Ennore, Kolkata, Paradip, Haldia, Dubai, Sharjah, Fujairah, UAE.